Table of Contents

What Is Robotics?

Robotics is an interdisciplinary field of engineering and computer science focused on the design, construction, programming, and operation of robots—machines capable of sensing, processing information, and acting in the physical world.

Scope of Robotics

Robotics‑explained combines multiple disciplines:

-

Mechanical engineering (structure and movement)

-

Electrical and electronics engineering (sensors, motors, power)

-

Computer science (software, control, AI)

-

Artificial intelligence and data analytics

Robotics vs AI vs IoT vs Automation

| Technology | Primary Role | Example |

|---|---|---|

| Robotics | Physical action | Robotic arms assembling cars |

| AI | Intelligence & learning | Vision-based defect detection |

| IoT | Connectivity & data | Sensors sending robot data to cloud |

| Automation | Rule-based processes | Conveyor belt systems |

Robotics often integrates AI and IoT but is distinct because it operates in the physical world.

Evolution of Robotics

-

1960s–1980s: Industrial robots for repetitive tasks

-

1990s–2000s: Computer-controlled and programmable robots

-

2010s–present: Intelligent, autonomous, and collaborative robots

Core Components of a Robotic System

A robotic system consists of both hardware and software components working together.

Key Components Overview

| Component | Function |

|---|---|

| Sensors | Perceive environment |

| Actuators | Enable movement |

| Controllers | Process data and commands |

| Power systems | Supply energy |

Sensors and Perception Systems

Common sensors include:

-

Cameras (vision)

-

LIDAR and radar (distance mapping)

-

Force and torque sensors

-

Temperature, proximity, and pressure sensors

These allow robots to interpret real-world conditions.

Actuators and Motion Control

Actuators convert energy into motion:

-

Electric motors

-

Hydraulic systems

-

Pneumatic actuators

Motion control algorithms ensure precision, speed, and safety.

Controllers and Embedded Systems

Controllers act as the robot’s “brain”:

-

Microcontrollers

-

Embedded processors

-

Industrial PLCs

They execute control logic and integrate sensor data.

Power Systems and Energy Management

Robots may use:

-

Batteries (mobile robots)

-

Direct power supply (industrial robots)

-

Hybrid systems

Efficient energy management is critical for autonomy.

Types of Robots

Robots are categorized based on function, environment, and autonomy.

Major Robot Categories

| Type | Example Use Case |

|---|---|

| Industrial robots | Manufacturing and welding |

| Service robots | Cleaning, delivery |

| Medical robots | Surgery, rehabilitation |

| AMRs | Warehouse navigation |

| Cobots | Human-robot collaboration |

Industrial Robots

-

Fixed robotic arms

-

High precision and speed

-

Common in automotive and electronics manufacturing

Service Robots

-

Professional (hospital robots, inspection drones)

-

Personal (vacuum cleaners, companion robots)

Medical and Healthcare Robots

-

Surgical robots (e.g., minimally invasive surgery)

-

Rehabilitation and assistive robots

-

Pharmacy automation

Autonomous Mobile Robots (AMRs)

-

Navigate dynamically using sensors and AI

-

Used in warehouses, factories, and hospitals

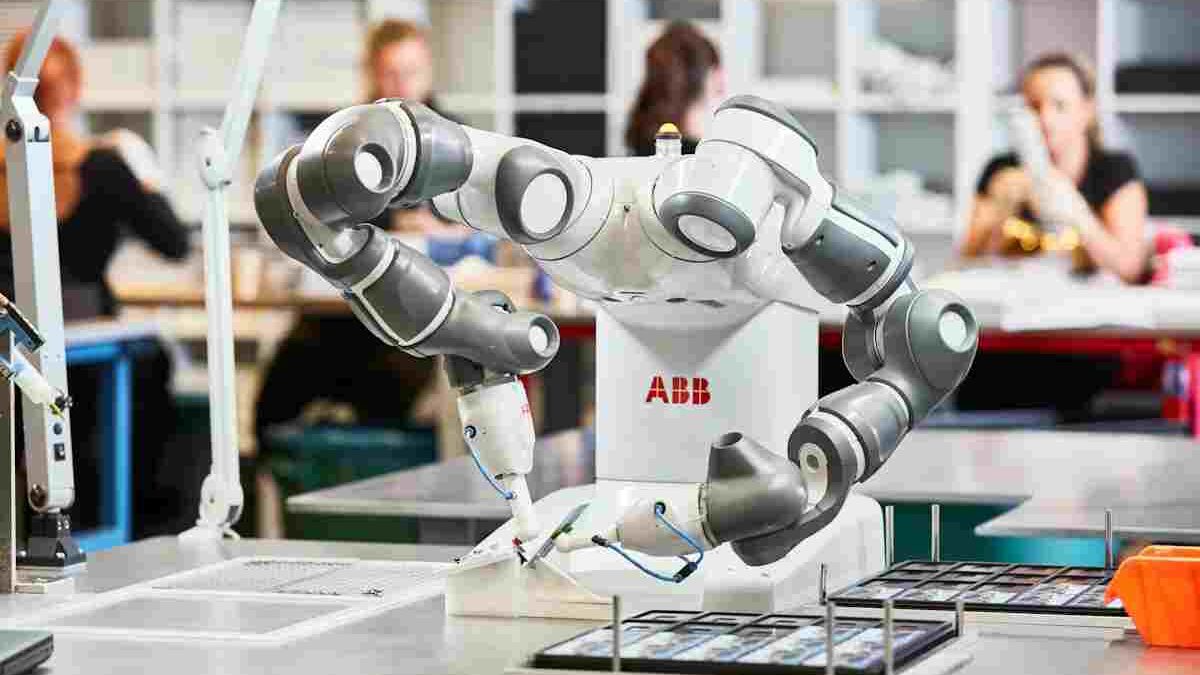

Collaborative Robots (Cobots)

-

Designed to work safely alongside humans

-

Lower cost and easier deployment

Robot Architecture and Design

Robotic architecture defines how components are structured and interact.

Physical vs Logical Architecture

-

Physical architecture: Mechanical layout, joints, materials

-

Logical architecture: Software layers, control logic, data flow

Mechanical Design Considerations

-

Degrees of freedom (DoF)

-

Payload capacity

-

Material strength

-

Environmental resistance

Control System Architecture

Common control approaches:

-

Open-loop control

-

Closed-loop (feedback) control

-

Model predictive control

Software Frameworks Used in Robotics

| Framework | Purpose |

|---|---|

| ROS (Robot Operating System) | Middleware and tools |

| Gazebo | Simulation |

| OpenCV | Computer vision |

| MoveIt | Motion planning |

Robotics and Artificial Intelligence

AI enables robots to learn, adapt, and make decisions beyond pre-programmed rules.

Role of AI in Robotics

AI improves:

-

Perception

-

Decision-making

-

Autonomy

-

Adaptability

Computer Vision and Object Recognition

AI-powered vision allows robots to:

-

Identify objects

-

Detect defects

-

Track movement

-

Understand environments

Natural Language Processing (NLP)

NLP enables:

-

Voice-controlled robots

-

Human-robot interaction

-

Social and service robots

Decision-Making and Autonomy

AI techniques used:

-

Machine learning

-

Reinforcement learning

-

Path planning algorithms

Robotics in Industry and Real-World Applications

Robotics adoption is accelerating across sectors.

Industry Applications Overview

| Industry | Robotics Use |

|---|---|

| Manufacturing | Assembly, welding |

| Healthcare | Surgery, diagnostics |

| Agriculture | Harvesting, monitoring |

| Logistics | Sorting, picking |

| Defense & space | Exploration, surveillance |

Manufacturing and Assembly

Robots improve:

-

Throughput

-

Accuracy

-

Worker safety

Healthcare and Surgical Robotics

Benefits include:

-

Reduced invasiveness

-

Higher precision

-

Faster recovery times

Agriculture and Farming Automation

Examples:

-

Autonomous tractors

-

Crop monitoring drones

-

Robotic harvesters

Logistics and Warehousing

AMRs and robotic arms handle:

-

Order picking

-

Sorting

-

Inventory management

Defense, Space, and Exploration

Robots operate in:

-

Hazardous environments

-

Space missions

-

Disaster recovery zones

Robotics and IoT Integration

IoT enhances robotics by enabling connectivity and data intelligence.

How IoT Enhances Robotic Intelligence

-

Real-time monitoring

-

Predictive maintenance

-

Fleet coordination

Cloud Robotics and Edge Computing

| Model | Advantage |

|---|---|

| Cloud robotics | Scalability, learning |

| Edge computing | Low latency, reliability |

Security and Data Challenges

Key risks:

-

Cyberattacks

-

Data privacy

-

Network dependency

Programming and Testing in Robotics

Common Programming Languages

-

Python (AI, ROS)

-

C++ (performance-critical systems)

-

Java (enterprise robotics)

-

MATLAB (simulation and control)

Robot Operating System (ROS)

ROS provides:

-

Hardware abstraction

-

Communication tools

-

Simulation support

-

Large open-source ecosystem

Simulation and Testing Environments

Popular tools:

-

Gazebo

-

Webots

-

V-REP (CoppeliaSim)

Robotics QA, Validation, and Safety Testing

Focus areas:

-

Functional testing

-

Stress testing

-

Compliance with safety standards (ISO, IEC)

Benefits and Challenges of Robotics

Key Benefits

-

Increased efficiency and productivity

-

High accuracy and consistency

-

Scalability across operations

-

Improved workplace safety

Challenges and Limitations

| Challenge | Impact |

|---|---|

| High initial cost | Slower adoption |

| Complexity | Skilled workforce required |

| Maintenance | Downtime risk |

| Ethics | Job displacement concerns |

Careers and Skills in Robotics

Robotics Engineering Roles

-

Robotics engineer

-

Automation engineer

-

AI/ML engineer

-

Mechatronics engineer

Skills Required

-

Mechanical design

-

Embedded systems

-

Programming and AI

-

Control theory

-

Data analytics

Robotics Jobs and Future Demand

Demand is growing across:

-

Manufacturing

-

Autonomous systems

-

Smart infrastructure

Learning Paths and Certifications

-

Robotics degrees

-

Online platforms (ROS, AI courses)

-

Industry certifications

Future Trends in Robotics

Emerging Robotics Trends

| Trend | Description |

|---|---|

| Humanoid robots | Social and service roles |

| Self-learning robots | Continuous adaptation |

| Smart city robotics | Urban automation |

| Human-robot collaboration | Augmented workforces |

Autonomous and Self-Learning Robots

Advances in AI enable robots to:

-

Learn from experience

-

Adapt to unknown environments

Robotics in Smart Cities

Applications include:

-

Traffic management

-

Infrastructure inspection

-

Public safety

Robotics vs Automation vs Artificial Intelligence

Key Differences and Overlaps

| Aspect | Robotics | Automation | AI |

|---|---|---|---|

| Physical action | Yes | Sometimes | No |

| Intelligence | Optional | No | Yes |

| Learning | Limited | No | Core feature |

When to Use Robotics vs Pure Automation

-

Use automation for repetitive digital processes

-

Use robotics when physical interaction is required

-

Use AI to add intelligence and adaptability

Final Thoughts

Robotics sits at the intersection of engineering, AI, and automation, driving the next wave of industrial and societal transformation. Understanding robotic fundamentals, architectures, and applications is essential for business leaders, engineers, and future professionals navigating an increasingly automated world.